PCD Pneumatic Conveying Dryer Technical Parameters

Type | Moisture(kg/h) | Equipped power(kw) | Occupied area(m2) | Height(m) |

PCD50 | 50 | 7 | 16 | 9 |

PCD100 | 100 | 13 | 26 | 11 |

PCD200 | 200 | 21 | 35 | 11 |

PCD250 | 250 | 24 | 51 | 13 |

PCD500 | 500 | 43 | 78 | 13 |

PCD1000 | 1000 | 100 | 105 | 15 |

PCD1500 | 1500 | 150 | 200 | 16 |

PCD Pneumatic Conveying Dryer Maintainance

Daily maintenance contents:

(1). Check the automatic drain valve on the front filter before

each shift.

(2). Check whether the change of tower and lift is normal.

(3). Check operating conditions, inlet pressure, inlet temperature

and air flow.

(4). Check for moisture indicators, blue for dry and pink for

moisture.

(5). Check whether the muffler is dirty, and the regeneration tower

back pressure is too high to indicate that the muffler needs to be

replaced.

(6). Check the pressure drop of the front filter and the back

filter, if the pressure drops more than 0.5 bar, change the filter

element.

Monthly maintenance contents:

(1). Check the control gas of the unheated and airflow

dryer.Replace when necessary.

(2). Check the filter element of air flow dryer guide filter, if

necessary, please replace it.

(3). Check the suction filter of air flow dryer, if necessary,

please replace it.

Maintain content quarterly:

Check the front and rear filters, check for blockages and possible

damage, and replace them as needed. Purge the relief valve with

compressed air. Check the dew-point status of the output.

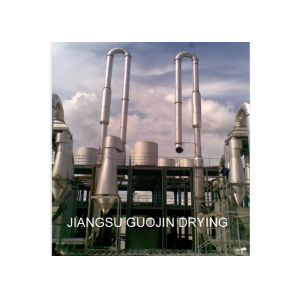

PCD Pneumatic Conveying Dryer Sketch of Structure